Meet The Robot Frying Your Food At White Castle

Flippy lives quietly outside Chicago, but may be coming to a White Castle near you.

We've previously reported on Flippy, a robot arm, manufactured by a company called Miso Robotics. It exists for one purpose: to make your fast food. You all knew this was coming, right? (Of course you did.) Robots and machines already assemble a lot of your industrial packaged goods, it was just a matter of time before a mechanical army would be the one slinging your burgers and fries. For ages, actually seeing a robot put together parts of your meal might have seemed like a slightly distant dream, but guess what, everyone? It's happening.

What is Flippy the robot?

White Castle is rolling out a new fleet of 100 Flippys (Flippy 2, to be exact) gradually within the next few years, and these robots are specifically dedicated to the deep fryer station. I'm talkin' fries, chicken rings, fish patties—if part of your lunch is taking a bath in oil before it gets to you, those 100 Flippy units'll be doing all the cooking.

But notice I specified that it's Flippy 2, not the original version. Flippy's been through iterations to upgrade certain abilities, one of which involves recognizing specific types of foods in different bins on its own, which a White Castle rep explains further in my following interview.

Flippy had a bit of a rough start; after its first day on the job at a Pasadena Caliburger (this unit was specifically designed to cook burgers), the machine was overwhelmed with orders and had to be taken offline after just one day. Nobody said restaurant work was easy.

At the moment, there's only one Flippy model that's in live production at any of White Castle's brick-and-mortar locations, and that so happens to be at a spot in Merrillville, Indiana, just outside of The Takeout's homebase of Chicago. I asked if I could come see Flippy, and White Castle said yes, so I moseyed on over to see this thing in action.

Before I went into the White Castle kitchen to observe, I sat down with White Castle District Supervisor, Dianna Williams, to ask her some questions about Flippy—the first version was installed in September 2020 and Flippy 2 came in November 2021. When I arrived, Williams, who manages 14 stores, was in back packing up orders to help with lunch rush. Out of the corner of my eye, I saw Flippy scooting around back and forth, shuttling back and forth from multiple fry baskets to a bagging station.

All about Flippy, White Castle’s robotic fry cook

The Takeout: Was this one of the first locations to get Flippy?

DW: This is the only White Castle location with Flippy right now, currently.

TO: The whole country?

DW: Period. You'll see the original, as I like to say, the only one, at the moment.

TO: So, Flippy's been around for a bit.

DW: This version's been around since November. It's a little different, but this newer version was definitely what we needed. The first version still required a lot of steps for the team, it required two team members to kind of operate it.

I was super excited when we got this version because instead of having two team members kind of work that area, we have one. And it's great because now, we can repurpose that team member to help take care of customers, create memorable moments, things like that.

TO: I can see it's busy back there, so having someone back on the line to help out is probably really good.

DW: It's definitely a benefit.

TO: Do you just have one employee helping with Flippy?

DW: So what Flippy does, is he cooks all of the products. We have what we call AutoBins. We put the product in, and we also have a food dispenser for our fries. So Flippy will take a basket, go to the AutoBins, and the food from the AutoBins will drop in the basket. Then he'll cook it, bring it up, and dump it to our front bag station. So it takes that entire process away from the team members, who aren't having to do that.

TO: Is that a dangerous job? Being on the fry station?

DW: Well, for us, that station is our most complex station, so that's why I think we put a major focus on that area. During our peak hours, at times we needed two team members to keep up. We have a large menu when it comes to our fryer products.

Working around hot oil is always a risk. I think with the fryer area, as long as you follow protocol, then there's really no high risk, but that is one thing we're able to eliminate. With a team member not having to handle baskets, then we have no risk with them and hot oil now.

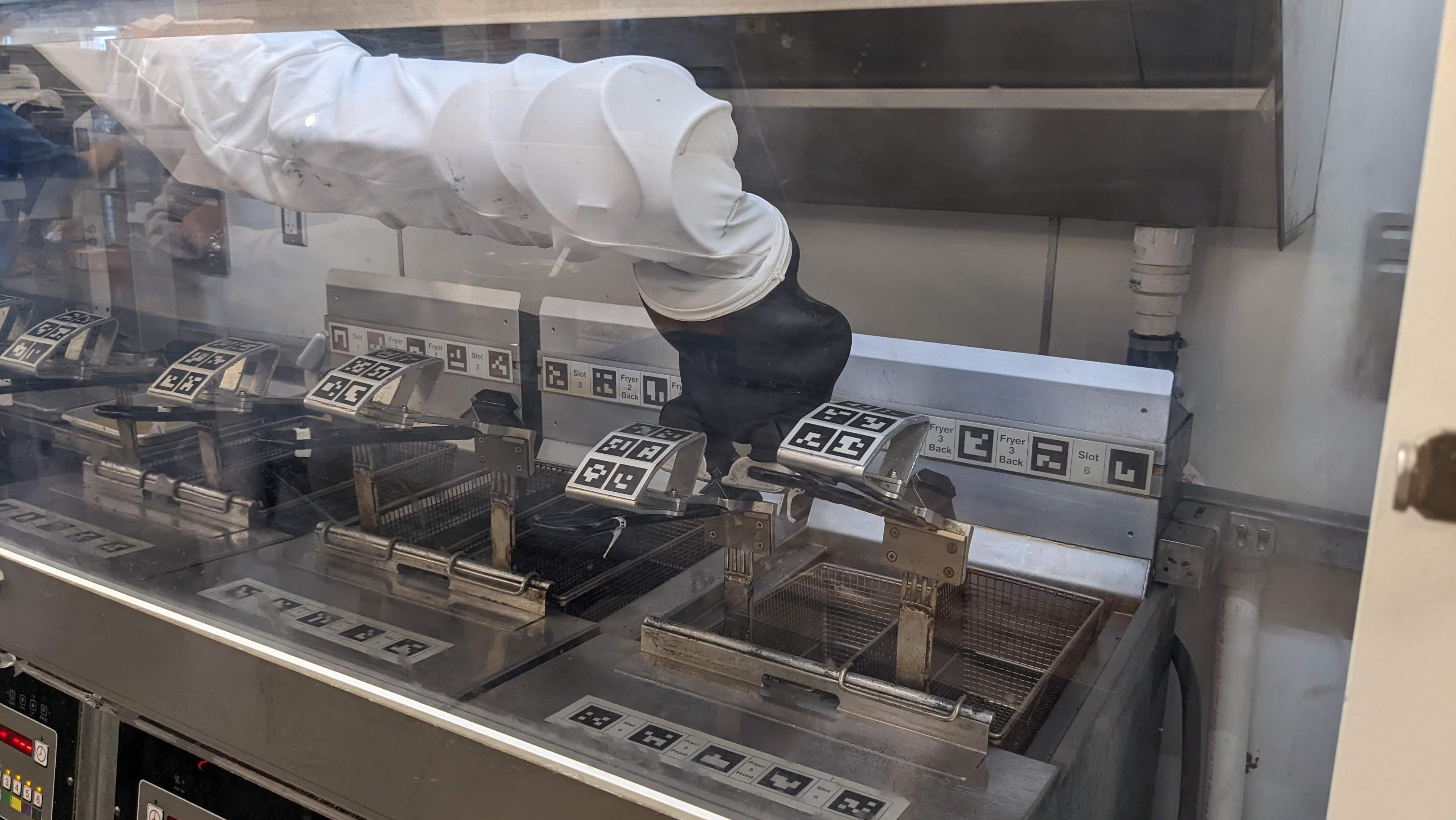

TO: I noticed there's a Plexiglass wall.

DW: Flippy's moving and grabbing at different things, so it's there to protect our team. So no one gets underneath, in its way.

TO: If somebody does get in the way, does Flippy know to stop?

DW: There are some sensors in there, but Miso [Robotics] has done a good job with making it so that you'd really have to work to get under that barrier.

TO: So it ends up being your fault if Flippy bonks you or something.

DW: [laughs] Yeah. And if any time we have to lift the barrier, we stop Flippy. There's a home station off to the side, like if we need to get in there manually, for cleaning reasons.

TO: Does Flippy replace two people?

DW: One team member is kind of what we compare it to. We've taken that team member and put Flippy there instead for 24 hours a day. People ask why, and it's to help our team and enhance it.

TO: And not to replace?

DW: No, not at all! We're looking for ways to get faster and to be more efficient, not to replace, because we always need more team members to interact with a customer.

So we can take that person now, and help face-to-face interactions with a customer and help move the line. Everyone knows, just what we went through last year [referring to the pandemic], so that was help, because Flippy really just is an extra hand.

TO: Do customers know about Flippy?

DW: I was just sitting out here [in the dining room] on my laptop earlier, and I could hear some customers at the front counter, talking about him. "Look at him cooking fries. I wonder, does he ever call off?" You know, making jokes. They definitely notice.

TO: In terms of maintenance, if something gets messed up, what are you supposed to do?

DW: We have a great partnership with Miso. They have a support team that actually monitors Flippy 24/7, around the clock, and so if we have any issues, we have a support line that we contact.

TO: How do you feel about Flippy? Was it weird at first?

DW: At first it was something we all had to get used to, but I think now we've gotten used to it.

TO: Do people have nicknames for Flippy?

DW: You know what? No, we call it Flippy. but I have a habit of saying "He." I just call him that. [Laughs]

What Flippy looks like in action

Williams took me to the back where I got to watch Flippy work up close. The robotic arm moved fluidly back and forth, shuttling from food bin to fryer basket. Its motions were smooth, with no stuttered motions or wobbly grip. If anything, Flippy's movement reminded me sort of like a bird's, deliberate and in bursts.

I watched as Flippy went over to the loading station, where it took a bin of uncooked product, and zipped it over to a hot deep fryer. The arm remained on standby as the food cooked, and when it was done, Flippy picked up the basket with its clamp-like grip, and shook the basket to get the excess oil off the food. This was the most human-like motion Flippy would exhibit while I was watching.

I looked around at the kitchen staff, who weren't phased by Flippy one bit. They were all busy working on their own tasks. If my coworker was a robot I'd probably be staring at it all day, but I suppose you get used to it pretty quick.

Did it feel like Flippy was there to replace people? It was hard to say, but my gut impression was that the robot honestly wasn't there to replace as much as some people fear. Consistency on a fry station isn't easy, and as Williams mentioned, this left an employee free to interact with the steady stream of customers that were coming to the counter and through the drive-thru during my visit.

But then I crunched some very basic numbers.

The cost of Flippy vs. the cost of human employees

Flippy's pricing, according to Miso Robotic's website, starts at $3,000 a month. That's $36,000 a year.

A full-time worker in Indiana (where White Castle's Flippy is stationed), at $7.25 an hour, would make $15,080 per year, for a 40 hour work week. Considering Flippy works pretty much around the clock, it's standing in for three slightly over four full time workers [thank an astute commenter to catch my math slip-up], save for short cleaning breaks. In total, those four-ish employees would earn around $60,000, so when it comes down to it, Flippy would save that White Castle location nearly $24,000 per year in terms of labor.

Savings would also vary by state. Illinois minimum wage is $12 per hour, meaning a White Castle location stands to save over $64,000 in labor per year, should it install a Flippy unit. That is a lot of money, and an employee that never, ever has to call out sick.

Is Flippy the future of fast food?

Is the technology perfect? I'm sure it isn't. Just like any complicated tool, Flippy needs maintenance, and I'm sure some of the nuts and bolts will figuratively pop off now and again, in which case a person will have to step in and do some "old-fashioned cooking," as Williams says. But if White Castle is willing to put its money on 100 of them, don't be surprised if you see more Flippys pop up at other restaurant chains.

I sat down afterwards for lunch. The fries and the chicken rings that I watched Flippy fry were perfectly hot and crisp, and I wouldn't have known it was all done by a robot if I hadn't seen it with my own eyes.

I know the idea of robots cooking your food is strange for some people, who probably also imagine a sentient being who's about to zap a laser at your face during a Terminator-type scenario. But I get the feeling that if the fries and chicken rings are good, most people will be too busy eating to care all that much.